Est. 2013

We are Specialised in Commercial Kitchen Flooring

Our meticulous process includes diamond grinding, epoxy cove and fall to drains, and anti-slip cement flooring for a clean, safe, and hygienic kitchen environment. Watch our video to see our expert floor preparation and flawless finishes.

Our Solutions for your Kitchen Floor

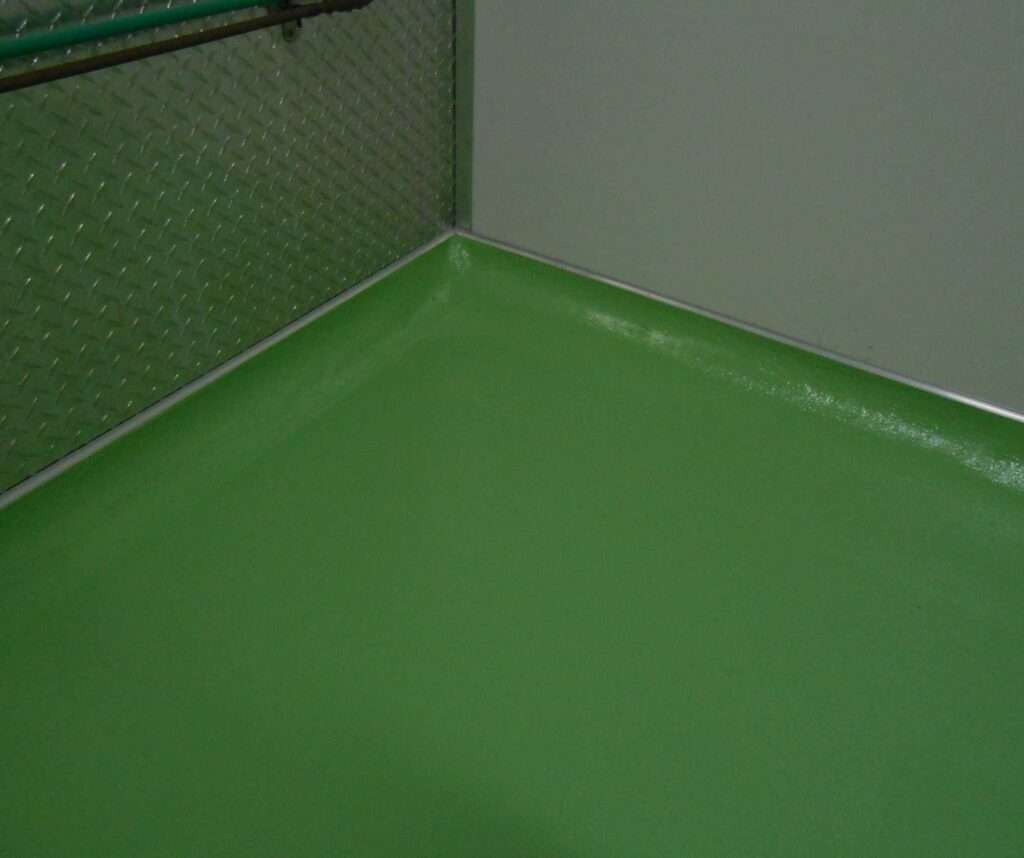

Hygine Epoxy cove

A hygiene epoxy screed cove offers numerous benefits in commercial kitchens. It provides a seamless and hygienic surface that is resistant to chemicals, stains, and bacteria growth. Its durable and easy-to-clean nature ensures a long-lasting and safe environment for food preparation.

Regions we serve

Buckle up, folks! We’re on the move and bringing our top-notch epoxy flooring solutions to a variety of areas. From Sydney metro to Central Coats, Newcastle to Sutherland, and even Wollongong and Kiama, we’ve got you covered. So if you’re ready to revamp your floors, just give us a call – we’ll be there in a flash!

Our Warranty

We offer a 5-year industry warranty on all our products and services. This warranty covers peeling, delamination and lifting. We stand behind the quality of our workmanship and materials, ensuring your floors remain in pristine condition for years to come. Contact us today for durable and reliable epoxy flooring solutions.

Benefits of Commercial Epoxy flooring in kitchens

Seamless and Easy-to-clean Surface: Epoxy cove flooring provides a seamless surface that is easy to clean, ensuring that dirt, grease, and bacteria have no place to hide.

Prevents Accumulation of Contaminants: The cove design of epoxy flooring prevents the accumulation of dirt, debris, and moisture in hard-to-reach corners, reducing the risk of bacterial growth and contamination.

Enhanced Sanitation: With its smooth and non-porous surface, epoxy cove flooring can be easily sanitized, making it an ideal choice for maintaining high levels of cleanliness in commercial kitchens and food preparation areas. Contamination.

Recent Blog Posts

Frequently Asked Questions

Epoxy flooring offers several advantages in a commercial kitchen setting that make it an ideal choice. Here are some of its benefits:

- Durability: Epoxy flooring is highly durable and can withstand the heavy traffic of a busy commercial kitchen.

- Ease of Maintenance: With its seamless surface, epoxy flooring is easy to clean and maintain, helping to uphold essential hygiene standards.

- Slip Resistance: Epoxy floors can be tailored with anti-slip additives to increase grip, reducing the risk of accidents in the kitchen.

- Chemical Resistance: Resistant to a wide range of substances, epoxy flooring is impervious to chemical spills that may occur in a kitchen environment.

- Aesthetically Pleasing: Epoxy flooring is available in a variety of colors and finishes, enabling customization to suit the aesthetic of any commercial kitchen.

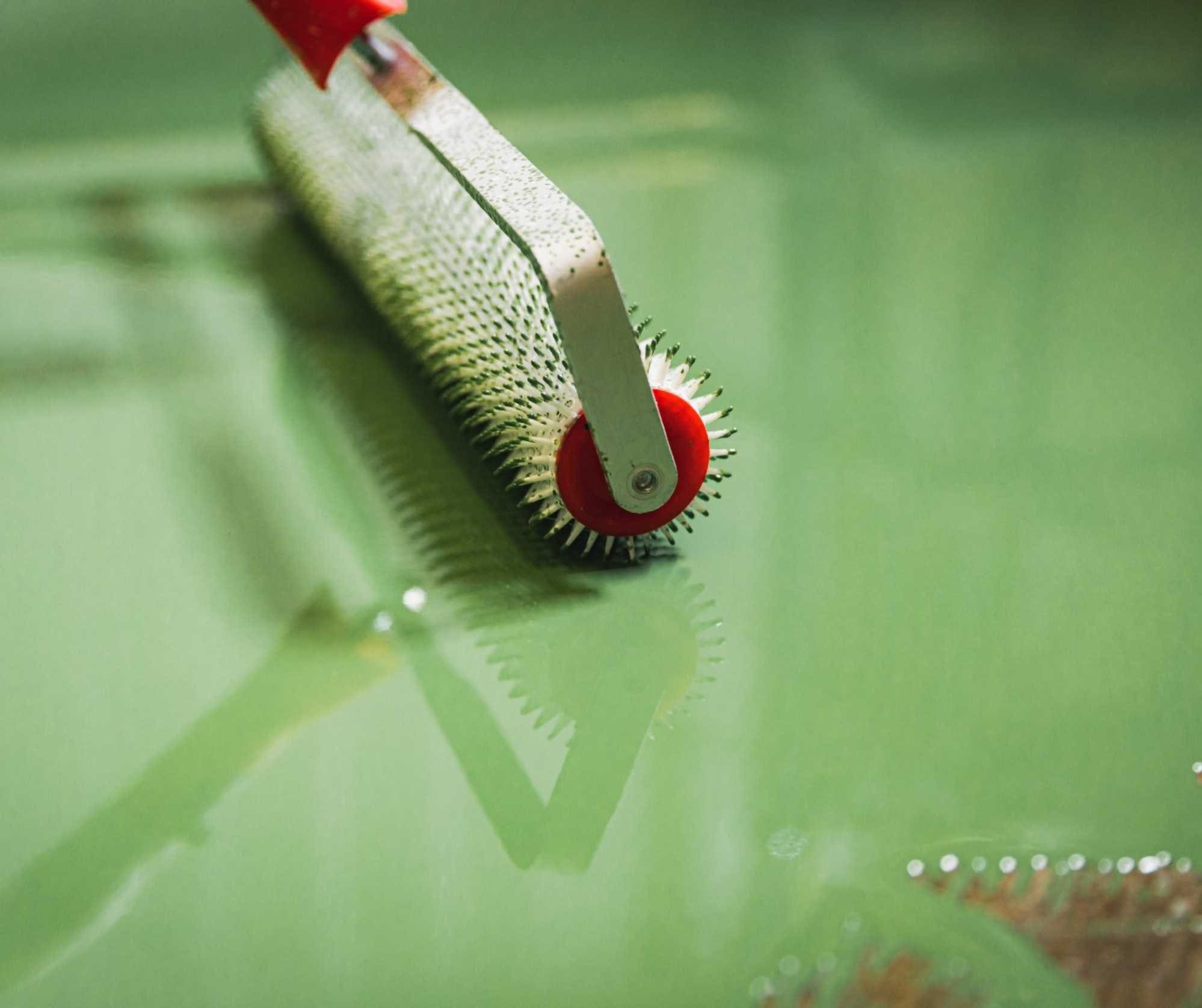

The process of installing epoxy flooring begins with surface preparation, which includes cleaning and grinding the concrete subfloor to remove any existing coatings, oil, or grease. Next, any cracks or pits in the concrete are filled with an epoxy patching system. Once the surface is prepared, a prime coat of epoxy is applied and allowed to dry for several hours. Following this, one or two coats of epoxy are rolled onto the surface, with optional decorative flakes or a non-slip aggregate added for extra texture. After each coat, the surface is allowed to cure for several hours. Finally, a clear topcoat is applied to seal and protect the floor. The entire process typically takes 2-3 days, but curing times can vary based on temperature and humidity.

Coving refers to the curved, seamless joint between the floor and wall or between the floor and equipment bases. In commercial kitchens, coving plays a crucial role in maintaining a clean and hygienic environment. It eliminates sharp corners where dirt, grime, and bacteria can accumulate, making cleaning more efficient and effective. Additionally, coving provides waterproofing benefits. It helps to prevent water and other liquids from seeping into the wall-floor junction, which could otherwise lead to structural damage or mold growth. Beyond hygiene and safety, coving also enhances the aesthetic appeal of the space, providing a neat, professional finish to the epoxy flooring.

Fall to drain, also known as slope to drain, is an important aspect of epoxy flooring in commercial kitchens. It refers to the gradual angle of the floor that directs any liquids or spills towards a designated drainage point. This feature is especially crucial in commercial kitchens where there are high chances of spills and splatters from food and beverages. The fall to drain helps to prevent pooling of water or other liquids, reducing the risk of slips and falls for employees. It also aids in the easy and efficient cleaning of the floors, as any spills can be quickly directed towards the designated drain.

Epoxy flooring is known for its durability and toughness, making it an ideal choice for high foot traffic areas such as commercial kitchens. With the addition of a topcoat, epoxy flooring can withstand heavy use and constant movement without showing signs of wear or damage. This makes it a perfect choice for busy commercial kitchens where employees are constantly moving around and equipment is being pushed or wheeled across the floor. Epoxy flooring also has a high resistance to scratches and abrasions, making it highly suitable for commercial kitchen environments.

Proper maintenance is essential for ensuring the longevity and performance of epoxy flooring in commercial kitchens. Regular cleaning with mild soap and water is usually sufficient to keep the floors looking their best. However, it is important to avoid using harsh chemical cleaners or abrasive tools as they can damage the surface of the epoxy. Additionally, any spills should be cleaned up promptly to prevent staining or etching on the surface. It is also recommended to have the epoxy flooring re-sealed every few years to maintain its protective layer and keep it looking new.

Yes, there are various aesthetic options available for epoxy flooring in commercial kitchens. Epoxy flooring can be customized to match the design and style of the kitchen, with a variety of colors and patterns to choose from. Some options even include adding flakes or chips for a textured look or incorporating logos or designs into the floor. This not only adds to the aesthetics of the kitchen but also helps with safety, as different colors or designs can be used to designate specific areas for different purposes.

Epoxy flooring offers many safety benefits in commercial kitchens. Its non-slip surface helps to prevent accidents and injuries caused by slips and falls, which can be common in busy kitchen environments. Additionally, epoxy flooring is resistant to fire and chemicals, creating a safer working environment for employees. This type of flooring also has a seamless design, eliminating any cracks or crevices where bacteria or germs can accumulate, promoting a hygienic environment for food preparation and handling.

Yes, epoxy flooring can be used in other areas of a commercial kitchen besides the main floors. It is commonly used on walls and countertops, providing a durable and easy-to-clean surface that can withstand the demands of a busy kitchen. Epoxy coatings can also be applied to concrete floors in walk-in coolers or freezers, creating a seamless and waterproof surface that is resistant to extreme temperatures. Additionally, epoxy can be used on kitchen equipment and appliances, providing a protective coating that is resistant to stains, chemicals, and wear and tear.

Polyurethane cement is a type of epoxy flooring that has additional benefits compared to traditional epoxy coatings. It offers superior durability and strength, making it ideal for high-traffic areas in commercial kitchens. Polyurethane cement is also highly resistant to chemicals and abrasions, making it suitable for use in areas where food and beverages are prepared. This type of flooring is also less prone to cracking and can withstand extreme temperatures, making it a more long-lasting option for commercial kitchens. Additionally, polyurethane cement has a faster curing time, allowing for quicker installation and less downtime for the kitchen operations. Overall, using polyurethane cement as an alternative to traditional epoxy flooring can provide additional benefits in terms of durability and functionality.