Est. 2013

Our Solutions for your Garage Floor

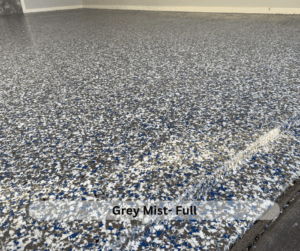

1. Full Flake System

Ultimate strength and durability of the epoxy system, ensuring a non-slip, seamless finish that effortlessly conceals imperfections.

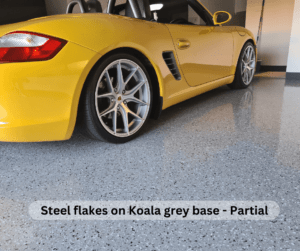

2. Partial Flake System

Incredible shine and easy maintenance of our partial epoxy flake system. A super glossy, showroom-worthy finish that is effortlessly cleaned.

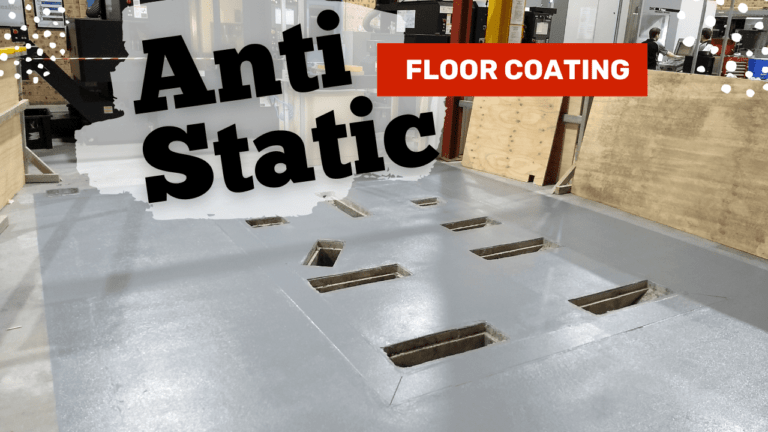

3. Solid Colour Epoxy

Experience the simplicity of solid colour epoxy. Effortlessly clean and choose from a variety of colours to enhance any environment.

4. Metallic Epoxy Flooring

The floatation of metallic oxide in a crystal-clear, high-solid epoxy creates a thick, glossy, and smooth finish with stunning 3D effects.

What is Our Process?

Free Quotation and Consultation

We'll have a delightful chat about your project and, if necessary, embark on an exciting site visit. After that, we'll whip up a fancy formal quote just for you. Stay tuned for greatness!

Floor Preparation and Grinding

We've got you covered with some serious floor grinding and patch-filling action to prep that surface for an exquisite coating. Each job is unique, so our systems are tailored to perfection.

Epoxy base and Flake Application

After completing the preparation and crack patching, we dive into the exciting phase of applying the epoxy base. and flake Broadcast on the we epoxy base.

Clear coat application- Completion

We apply a UV stable super clear polyaspartic coating to the entire floor. Now, it's time to revel in the sheer delight of your brand new, sparkling epoxy floor, t. Enjoy the magic!

Our Recent Projects

Top Epoxy Brands for Your Flooring

We use only the highest quality materials, such as 100% solid Australian-made low VOC epoxy, including renowned products like Hychem Supafloor, Sikafloor 264, or EP100 from APC.

To ensure a flawless finish, we begin by applying a full broadcast of vinyl flake in your chosen color, providing complete coverage and adding strength to your floor. This process enhances both the aesthetic appeal and the resilience of the epoxy surface.

To further protect and prolong the life of your epoxy floor, we apply a heavy coat of a UV-stable polyaspartic clear coat, such as Sparta 60, Sikafloor 550PA, or Hychem TL2. These superior products ensure the durability and longevity of your floor, making it resilient to the passage of time.

The entire process typically takes two days to complete. Following the application, there is a required drying time of 24 hours for foot traffic and 72 hours for vehicle traffic. This allows for proper curing and ensures the longevity of your epoxy floor.

Features and Benefits of Epoxy Flooring

Non Slip

Epoxy coatings are available in various levels of slip resistance, conforming to all industry standards.

High Performance

Epoxy is well-suited for high-traffic areas that are subject to impact from heavy vehicles and extreme wear.

Chemical Resistance

Epoxy flooring coatings are known for their seamless finish and exceptional chemical resistance.

Low VOC

Low VOC emissions, Low odour, Environment friendly. Safe for People and animals

Easy to clean

Epoxy floor coatings provide concrete with dust-proofing and create a seamless, easy-to-clean surface

Long Lasting

Epoxies with high solid content are resilient and durable, offering protection against impact and excessive wear.

Our Warranty

We offer a 5-year industry warranty on all our products and services. This warranty covers peeling, delamination, lifting, and hot tire pick-ups. We stand behind the quality of our workmanship and materials, ensuring your floors remain in pristine condition for years to come. Contact us today for durable and reliable epoxy flooring solutions.

Frequently Asked Questions

One of the main benefits of using epoxy flooring in a garage is its durability. Epoxy is known for its strength and resistance, making it perfect for heavy foot and vehicle traffic that typically occurs in a garage.

Another advantage of epoxy flooring is its easy maintenance. Unlike other types of flooring, such as concrete or wood, epoxy can be easily cleaned with just soap and water. This makes it a popular choice for garages, as spills and stains are common in this area.

In addition to being durable and low maintenance, epoxy flooring also offers a variety of design options. It can be customized with different colors, patterns, and even metallic flakes for a unique and stylish look. This makes it not only functional but also aesthetically pleasing.

The installation process of epoxy flooring involves several steps. First, the concrete surface must be properly prepared by cleaning and repairing any cracks or damage. Then, a primer is applied to ensure proper adhesion of the epoxy coating.

Once the primer has dried, the first layer of epoxy is poured and spread evenly across the floor using tools such as rollers or squeegees. This is followed by a second layer of epoxy, and any desired design elements or textures can be added at this stage.

After the epoxy has cured, a top coat is applied to provide additional protection and shine. The entire process usually takes about 2-3 days, including drying time.

The drying time for epoxy flooring can vary depending on factors such as temperature and humidity. Typically, it takes around 24 hours for the epoxy to dry to the touch and about 72 hours for it to fully cure. During this time, it is important to avoid walking or placing heavy objects on the floor to ensure a smooth and even finish.

Epoxy flooring is known for its durability and low maintenance requirements. To keep it looking its best, regular cleaning is recommended to remove any dirt, debris, or spills. This can be done with a mop or soft-bristled brush and a mild detergent.

In high traffic areas, it may be necessary to reapply a top coat every few years to maintain the protective layer. Additionally, it is important to avoid using harsh cleaning chemicals or abrasive tools on the epoxy surface as they can cause damage.

Yes, epoxy flooring can be customized to provide slip resistance by adding a non-slip additive during the installation process. This is particularly useful for garage floors where spills and wet surfaces are common. However, it is important to note that even with slip-resistant additives, proper precautions should still be taken when walking on the floor to prevent any accidents.

With proper installation and regular maintenance, epoxy flooring can last anywhere from 10-20 years. This makes it a long-term investment for homeowners and businesses.

Epoxy flooring offers a wide range of colors and designs to choose from, making it a popular choice for both residential and commercial spaces. Solid colors, metallic finishes, and even decorative patterns can be achieved with epoxy flooring. Some companies also offer the option to customize the color and design to fit the specific needs or branding of a business.

The best material to use for epoxy flooring in Australia would depend on the specific needs and requirements of the space. However, some common materials used include high-quality resins and hardeners that are designed to withstand heavy foot traffic and harsh chemicals. It is important to consult with a professional installer to determine the best material for your specific location and usage.

Hiring a professional for epoxy flooring installation has many benefits over attempting a DIY project. Firstly, professionals have the experience and expertise to properly prepare the surface and apply the epoxy coating, ensuring a long-lasting and high-quality finish. They also have access to specialized equipment and materials that may not be readily available to individuals attempting a DIY project. Additionally, professionals are trained in safety protocols and can ensure that the installation process is done safely and efficiently. Overall, hiring a professional for epoxy flooring can save time, money, and result in a more durable and aesthetically pleasing finish.

Typically, an epoxy floor is coverd udner 5 year warranty against peeling, delamination and hot tyre pickup.